- #Siemens step 7 course how to

- #Siemens step 7 course install

- #Siemens step 7 course software

- #Siemens step 7 course code

- #Siemens step 7 course professional

#Siemens step 7 course how to

You will have learnt how to create your own Data Blocks, Function Blocks, Functions and VAT Tables. You'll have an understanding of the most used instructions in Siemens STEP7 Professional and how you can incorporate them into your programs. You will have created and structured your programs using Networks. You will be able to have scheduled access to the Siemens Simulator, allowing you to download your programs and monitor them live via Siemens STEP7 Professional. You'll understand the basics of the Siemens S7-300 PLC including its hardware, addressing and wiring. Upon completion you will have designed multiple PLC programs from scratch using Siemens STEP7 Professional. #Siemens step 7 course code

Once enrolled you will be able to begin your training and further your skill-set to help improve your career opportunities.Īlready enrolled onto our Siemens S7 & TIA Portal Programming? Contact us for your exclusive Voucher Code and get 30% off. To get started, select Add to Cart and then go to the Checkout to create your MyScantime student account and enrol today.

#Siemens step 7 course professional

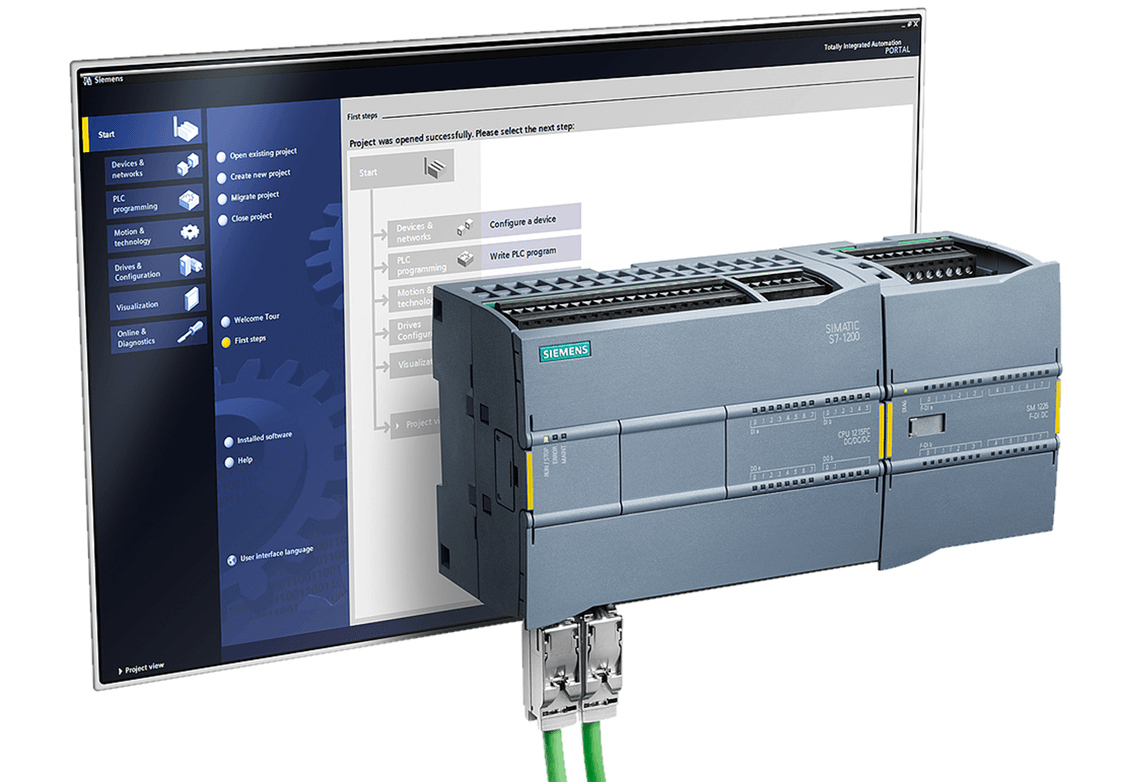

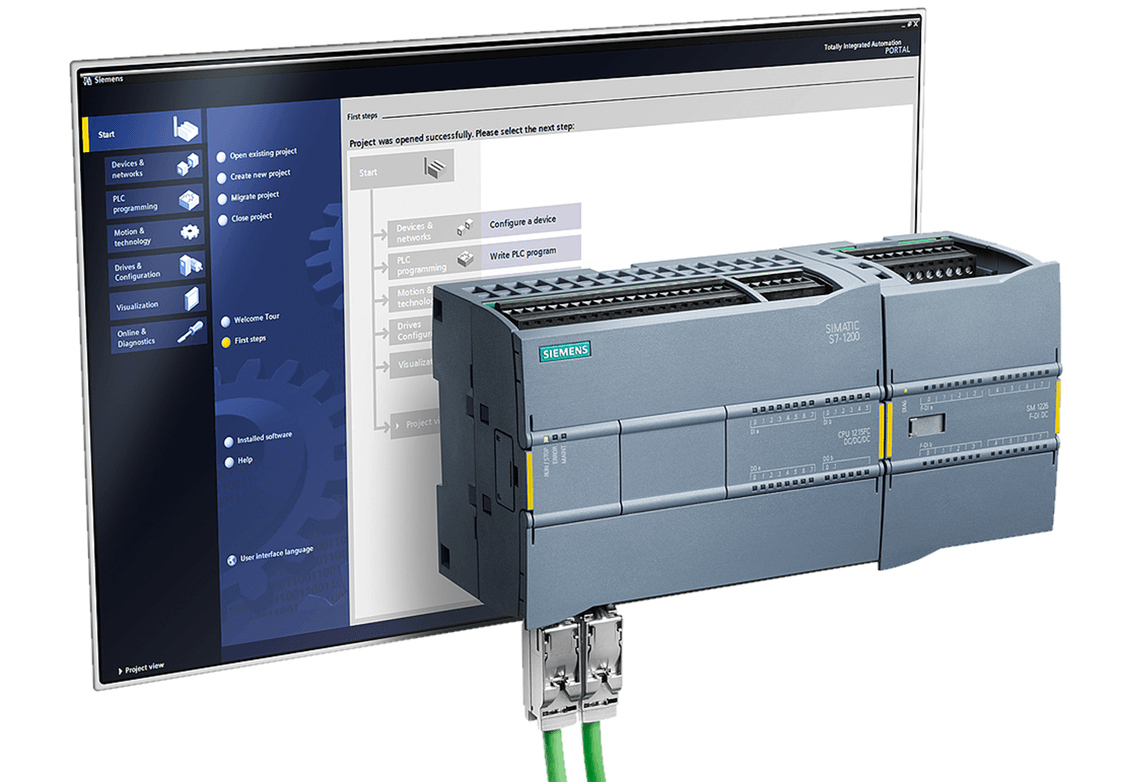

Our self-paced, Siemens STEP7 Professional Programming eLearning course has been designed by Controls Engineers who actively use Siemens STEP7 Professional on the shop-floor with live processes to help provide you with the correct experience required for shop-floor Engineers to work with Siemens PLCs in today's industry. These PLCs are the cornerstone of the Automation Industry and it's now becoming a necessity for Engineers (Electrical, Mechanical or Maintenance) to have some form of PLC experience.

#Siemens step 7 course software

Siemens S7 Programmable Logic Controllers are some of the most popular PLCs, worldwide and STEP7 Professional is one of the most commonly used software packages available and is used to program the S7-300 & S7-400 PLCs. ✅ Access to Siemens STEP7 Professional software Includes: ✅ 40+ Siemens STEP7 Professional programming tutorials and videos The maintenance engineer should also be capable of making an (original) backup of the program and be able to load it into the PLC.Learn everything you need to know to start using Siemens STEP7 Professional today

To make a backup of the changes made to the program.Programming a counter and time measurement is desirable.

To make links or to develop connections that changes the program conditions. The maintenance engineer must be able to read the documentation, understand the structure of the PLC and be aware of the most commonly used PLC instructions. To make the internal I/O status of the signal visible: – to call the ‘suspected’ section in the program – to make timer and counter files visible.

To make links or to develop connections that changes the program conditions. The maintenance engineer must be able to read the documentation, understand the structure of the PLC and be aware of the most commonly used PLC instructions. To make the internal I/O status of the signal visible: – to call the ‘suspected’ section in the program – to make timer and counter files visible. #Siemens step 7 course install

To install and to start the programming software. One should measure here with a universal meter. To determine that the signal of the ‘suspected’ unit will show at the correct PLC reference. To be able to identify if the PLC is still active and that there are no communication errors with the I/O or other coupled PLC’s. The maintenance engineer should therefore be capable of executing the following actions: This is necessary, because designers are not always able to design their programs to register every possible fault and the potential cause. These faults can be investigated via the programming terminal and the signal status can be presented dynamically. Problems are most likely to occur with the installation itself and this is reflected in the PLC by for instance a defective sensor, a badly working cylinder etc. The maintenance engineers should be capable of making small changes to the program. Programming and documenting the program is of less importance. With regard to PLC’s and programming software, the maintenance engineer needs to be able to access specific parts of the program and to examine the I/O status. One needs to have sufficient knowledge of the equipment, coupled with knowledge of the installation to be able to diagnose the problem and then solve the problem. This course recognises that maintenance personnel cannot build up a profound technical knowledge of all the equipment to be maintained. Global Contents Maintenance personnel are often confronted with equipment from several manufacturers.

0 kommentar(er)

0 kommentar(er)